What is Gear Motor?

A gear motor is an electromechanical device capable of transmitting motion. There are several types of geared motors. Different types are suitable for different applications. The design of a gear motor may depend on several factors. For example, its output speed and torque affect its efficiency. Likewise, its thermal and shock loads affect its reliability. The operation of the gear motor is very simple and can be integrated into various devices.

about Gear Motors

Geared motors consist of a motor, gears, and bearings in a housing and are typically used in applications that require a lot of force (torque) at low speeds. DC gear motors require battery power for precision variable speed applications such as wheelchairs, hospital beds, lifts and medical tables, power seats, and other automotive applications. AC gear motors run on AC power and are typically used in high-power applications such as lifts, jacks, and robots. Gearmotor accessories such as brackets, covers, and extension cables are used to protect, mount and drive gear motors.

How to Use Gear Motor

A gear motor is a form of electric motor. They are used to drive devices in industrial applications and home appliances.

A gear motor consists of an electric motor and a gearbox. The gearbox reduces the speed of the motor and increases the torque. It also takes into account losses due to sliding and friction.

Gearmotors are used in various applications including heavy lifting equipment, cranes, and commercial jacks. These types of applications are often used in conjunction with AC motors. However, they can be powered by DC power.

Most applications of geared motors are in industrial and commercial fields. Other typical applications include commercial jacks, hospital beds, can openers, and garage door openers.

Gearmotors can be designed with many different speeds and gear ratios. The best way to choose a geared motor is to study its specifications and performance curves. Selecting equipment based on specifications ensures the longevity and efficiency of the equipment.

Gear Motor for Sale

As industrial gear motor manufacturers, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need gear motor catalog pdf, don’t worry; more of our products are still being uploaded. You can email us directly, and we will reply within 24 hours!

-

34r-fx Series Parallel Shaft Ac 3-phase Inverter Duty Gear Motor

-

34R-WX Series Parallel Shaft AC Gearmotor

-

34R-Z Series Parallel Shaft AC 3-Phase Inverter Duty Gear Motor

-

42R6-FX Series Parallel Shaft AC Gear Motor

-

Metric 34R-W Series Parallel Shaft AC Gear Motor

-

Metric 34R-Z Series Parallel Shaft AC Gear Motor

-

Other Products

Gear Motor Applications

Geared motors are typically used in applications that require high output torque and low output shaft speeds. Furthermore, due to their compact design and modularity, they are an especially ideal solution where space and power are limited.

AGVs and AMRs

Medical

Car Wash Equipment

Food & Beverage

Packaging Equipment

Energy

How do I choose the best Gear Motor for my needs?

Compatibility is key when looking for the best-geared motor for your business. It is critical to determine whether the gear motor you are looking at meets the specific requirements of your application. Are gear motors matched for torque, speed, and efficiency? Once this is determined, investigate the intended gear motor’s thermal characteristics and design limitations. Ask about gearbox input speed, intermittent duty cycle, and gearbox yield strength to ensure you choose the gear motor that best suits your needs.

Gearmotor FAQs

When you are in the market to repair or replace an existing unit or install a new gear motor, there are many gear motors to choose from. Sumitomo has options that can be easily adapted to your application. To help you save time and time researching, we’ve compiled a list of frequently asked questions.

What is a gear motor?

Geared motors consist of a motor, gears, and bearings enclosed in housing. They are often used in applications that require a lot of force (torque) at low speeds. Geared motors driven by alternating current perform many high-power-related tasks, such as lifting, hoisting, and robotics. Brackets, covers, and extension cables mount, protect and drive gear motors.

How does a gear motor work?

The main functions within the gear motor are handled by the gear unit and its stages. These features transfer the force of the motor from the input to the output. Therefore, the gearing acts as a speed and torque converter.

In most applications, the gear unit usually reduces the motor speed while transmitting more torque than the motor itself can provide. With this in mind, the design of the reducer will determine whether the geared motor is suitable for light or medium loads and for short or long periods of energization.

The reduction ratio or gear ratio refers to how the gear unit reduces or increases the input speed of the motor (called the input speed). Another measure of a gear motor’s performance is its maximum torque on the output side. Torque is measured in Newton meters (Nm) and refers to the force of the gear motor and the load it can move with that force.

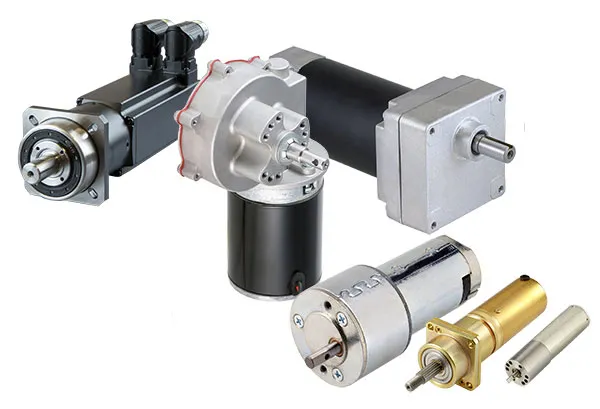

What types of gear motors are available?

The main factor that determines the type of geared motor is the shaft configuration of the gearhead. We offer three different designs such as right angle geared motors, parallel shaft geared motors and concentric units.

Where are gearmotors used?

The simple answer is – everywhere! Sumitomo units can be found in the parcel handling industry, the mining industry, the food and beverage industry, and more. Anything that needs to be moved – 9/10 is powered by some type of gear motor.

What information do I need to select the right gear motor?

To choose the right geared motor for your application, you need to know:

Application: Driven Machine Type

Daily business hours

Motor Horsepower (HP) and Speed (RPM)

Installation location

Ambient environment, temperature and humidity

Special environmental factors or operational requirements.